Production Facility

The Widest Product Range from 0,06kW to 3000kW

Factory

Since 1961, as the first and leading electric motor production plant in Türkiye, Gamak has exponentially increased its production capacity and turned into an integrated plant that produces every part of an electric motor internally. At the beginning of the 80's, our Dudullu-Istanbul facility was found on 330.00 m2 open - 60.000 m² closed area. with a covered area of 60.000 m² was established on 330.000m2 area in Istanbul-Dudullu. In addition to production departments as pressing, mechanical processing, winding, assembly, mold production, repair and maintenance, we also have an aluminum injection unit where lighter frames are produced. We also have a special production branch which can produce custom made motors and a motor test laboratory which is one of the few test stations in Europe. Our wire enameling facility is the first in Türkiye and one of few in the world. By enhancing employee development and our production and quality standards, we increase our production capacity and capability day by day.

Production Capacity

As one of the few electric motor factories in the world where lean production is gathered under one integrated plant, Gamak manufactures a wide range of 0,06kW - 3000kW aluminium and cast iron frames. We take our production and quality to the next level with our competent workforce and latest technology production lines. As one of the few electric motor manufacturers in the world producing its own wire, we draw out our wire in 0,2-1,32 mm range. Having one of the best test laboratories in Europe, we guarantee our products meets energy efficiency standards worldwise, IE1 to IE4. As a result of our R&D projects, we not only produce high-efficiency motors (IE3 – IE4)but also create distinctive designs for specific demands. Thanks to this potential, we answer all Customer needs in a dynamic and flexible manner.

Our expertise and experience gained in electric motors made us a strong player in wind turbine generators too. Wind turbines in Türkiye are now using the 4 MW power generators produced by Gamak.

Production Processes

Production Processes

In the pressing section high quality electrical steel, goes through the slitting process, the first phase of manufacturing. The tapes obtained in slicing are then cut by high-speed eccentric presses with pitched molds to form laminations of the stator and rotor packs.

In the pressing section high quality electrical steel, goes through the slitting process, the first phase of manufacturing. The tapes obtained in slicing are then cut by high-speed eccentric presses with pitched molds to form laminations of the stator and rotor packs.The packages, formed by placing 0.50 mm thick lamination sheets on top of each other, are sent to the winding workshop for wrapping, after riveting. In the press workshop we in addition manufacture the fan covers. After the air intake holes and binding holes of the fan covers are opened, fan covers are ready to be installed to the motors.

In the aluminum injection and foundry section, aluminum ingots are melted in natural gas or electric melting furnaces. Special aluminum alloy is used for the production of motor frames, covers, flanges and terminal boxes up to 200 frame sizes. High pressure vertical and horizontal aluminum injection presses, provide extremely tight textured aluminum parts.

In the aluminum injection and foundry section, aluminum ingots are melted in natural gas or electric melting furnaces. Special aluminum alloy is used for the production of motor frames, covers, flanges and terminal boxes up to 200 frame sizes. High pressure vertical and horizontal aluminum injection presses, provide extremely tight textured aluminum parts.

In the mechanical processing department, where there are hundreds of CNC processing machines and robot automation lines with high precision, parts such as shafts, covers, flanges and motor frames are processed. In a single setup we process all sides of the parts. In this way, axis distortions are prevented when all the parts are assembled. While the motor frame is being prepared for assembly, all these operations are performed in a single setup without moving the frame. Flanges and motor covers are treated on same basis and are processed in CNC machines with a fully automatic production line system.

In the mechanical processing department, where there are hundreds of CNC processing machines and robot automation lines with high precision, parts such as shafts, covers, flanges and motor frames are processed. In a single setup we process all sides of the parts. In this way, axis distortions are prevented when all the parts are assembled. While the motor frame is being prepared for assembly, all these operations are performed in a single setup without moving the frame. Flanges and motor covers are treated on same basis and are processed in CNC machines with a fully automatic production line system.

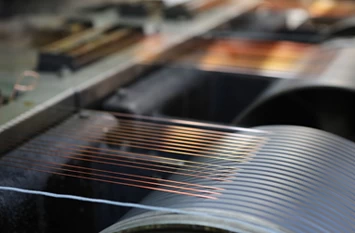

GAMAK is one of the few electric motor manufacturers in the world that produces its own wire. Our own copper coils are produced in the wire enameling plant. The copper, which comes in 8 mm, can be thinned to 2 mm and even smaller diameters. Copper wires are fed to mini-rolls running synchronized with enameling machines, are simultaneously enameled and drawn at the desired size. Copper wires enameled with two different varnishes are produced in N class i.e. 200oC heat resistant. One of the most important elements of our high quality motors is our self production of enameled copper wire, which undoubtedly comprises heart of the motor.

GAMAK is one of the few electric motor manufacturers in the world that produces its own wire. Our own copper coils are produced in the wire enameling plant. The copper, which comes in 8 mm, can be thinned to 2 mm and even smaller diameters. Copper wires are fed to mini-rolls running synchronized with enameling machines, are simultaneously enameled and drawn at the desired size. Copper wires enameled with two different varnishes are produced in N class i.e. 200oC heat resistant. One of the most important elements of our high quality motors is our self production of enameled copper wire, which undoubtedly comprises heart of the motor.

In the winding workshop with full automation winding lines, respectively all insulation materials are placed in stator packages, coils are prepared and placed in stator packages, and then wire connections and cables are installed. The inter-phase connections with insulating tubes are placed as protection. After the winding ends are are stitched, all of the stators are tested. Finally, the stators are dipped in H or F grade varnishes are baked to dry and harden.

In the winding workshop with full automation winding lines, respectively all insulation materials are placed in stator packages, coils are prepared and placed in stator packages, and then wire connections and cables are installed. The inter-phase connections with insulating tubes are placed as protection. After the winding ends are are stitched, all of the stators are tested. Finally, the stators are dipped in H or F grade varnishes are baked to dry and harden.

The resistance values of all assembled motors is measured, insulation testing is performed and current values are measured and recorded at no load. Rabbet covers are opened in CNC lathe after the winding stator is hammered into the aluminum frame. Following the installation of the balanced rotor, the covers are assembled, the terminal connections are completed and the terminal box is installed.After fan covers and fans are assembled, the labels of the motors are prepared. Values of test data of each motor produced, production date and detailed material information can be seen on all our motors.

The resistance values of all assembled motors is measured, insulation testing is performed and current values are measured and recorded at no load. Rabbet covers are opened in CNC lathe after the winding stator is hammered into the aluminum frame. Following the installation of the balanced rotor, the covers are assembled, the terminal connections are completed and the terminal box is installed.After fan covers and fans are assembled, the labels of the motors are prepared. Values of test data of each motor produced, production date and detailed material information can be seen on all our motors.

In custom-made production department, products with different features are produced according to the demands and needs of specific industrial companies. Thanks to our integrated production and ability to to produce all motor sub parts, we produce what other players cannot. Cast iron frames, stainless steel shafts are all manufactured just for a each and every Customer's need and designed for special applications like severe climatic conditions, water cooling tower usage etc., whatever is required by End User.

In custom-made production department, products with different features are produced according to the demands and needs of specific industrial companies. Thanks to our integrated production and ability to to produce all motor sub parts, we produce what other players cannot. Cast iron frames, stainless steel shafts are all manufactured just for a each and every Customer's need and designed for special applications like severe climatic conditions, water cooling tower usage etc., whatever is required by End User.

Two of the very important units that ensure continuity of our production are our mold design department and mold production workshop located within our R&D Center. Designs of the new molds and related tools, technical drawings are easily produced. After technical drawing stage, wooden models are made for the cast iron parts in our modeling house. All the molds that we use in manufacturing are produced with CNC machines with high precision. Lamination cutting; aluminum press injection for frames, covers, flanges; terminal box molds and plastic parts' injection molds are all produced in our mold production workshop.

Two of the very important units that ensure continuity of our production are our mold design department and mold production workshop located within our R&D Center. Designs of the new molds and related tools, technical drawings are easily produced. After technical drawing stage, wooden models are made for the cast iron parts in our modeling house. All the molds that we use in manufacturing are produced with CNC machines with high precision. Lamination cutting; aluminum press injection for frames, covers, flanges; terminal box molds and plastic parts' injection molds are all produced in our mold production workshop.

Our test and development laboratory ranks among the best in Europe. We can do 'load testing' up to 900 kW for newly designed motors or motors that have had their electrical ratings changed after being tested at nominal power. Newly designed motors are installed and tested at nominal power first. Current values, input power, losses, efficiency, power factor, moment, temperature increase under load until it reaches thermal equilibrium are measured and recorded. The noise levels of the motors are measured in a quiet room. Locked rotor tests are performed. At the end a test certificate is issued with all recorded value and curves like speed - moment - current. Our world standard laboratory is the heart of our R&D studies.

Our test and development laboratory ranks among the best in Europe. We can do 'load testing' up to 900 kW for newly designed motors or motors that have had their electrical ratings changed after being tested at nominal power. Newly designed motors are installed and tested at nominal power first. Current values, input power, losses, efficiency, power factor, moment, temperature increase under load until it reaches thermal equilibrium are measured and recorded. The noise levels of the motors are measured in a quiet room. Locked rotor tests are performed. At the end a test certificate is issued with all recorded value and curves like speed - moment - current. Our world standard laboratory is the heart of our R&D studies.

Medium voltage motors up to 3MW power level and 11kV voltage level as well as generators up to 5MW power level used in wind turbines are produced in this plant. MV production plant is equipped with a state-of-the-art automation system. All necessary processes such as high-speed balancing, full automation robot bandage, VPI varnish systems and robotic welding are carried out with highly modern and high-tech machines and full automation.

Medium voltage motors up to 3MW power level and 11kV voltage level as well as generators up to 5MW power level used in wind turbines are produced in this plant. MV production plant is equipped with a state-of-the-art automation system. All necessary processes such as high-speed balancing, full automation robot bandage, VPI varnish systems and robotic welding are carried out with highly modern and high-tech machines and full automation.